Renovating an RC building in Yamanashi and turning it into a sewing factory [Wall insulation/secrecy and toilet piping]

Renovated a used concrete (RC construction) property that used to be a parking lot and warehouse to become an apparel sewing factory.

AGLUCA, an apparel sewing factory operated by Ioku Ltd., has renovated a used property with exposed concrete in Yomotsu, Uenohara City, and aims to create a stylish and comfortable factory that is easy to work in.The company is conducting construction work while holding daily meetings with construction companies. I'm asking you to proceed.

In this article, we will introduce highly airtight high insulation, insulation materials (Styrofoam, Rock wool, sprayed urethane foam), and toilet piping with airtight taming.

Prerequisite information for this used property

・More than 40 years old

・Concrete poured (RC construction)

・The wall is not horizontal and is curved in places (in other words, a limp concrete wall)

・Botton toilet

・Originally used as a warehouse and parking lot, so there is no insulation and one side has no wall (windswept)

In this blog there are also

Installation of ceilings, ventilation systems, electrical piping, and air conditioning

There is also an article.

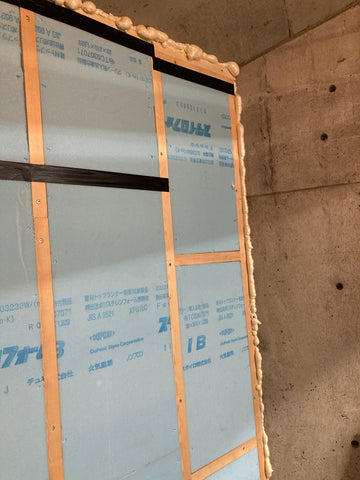

Attach a wooden frame to the concrete wall and level it.

Since the wall is uneven in some places, we use wood to adjust it so that it is level. Installed on the entire wall

You can see that the thickness of the wood between the front and back is different.

Construction of high insulation using Styrofoam insulation material

Styrofoam insulation material is cut and fitted (installed) on site to match the wooden frame, which has been constructed all over to maintain levelness.

In the case of concrete walls (reinforced concrete), Styrofoam, which is more resistant to moisture than rock wool or glass wool, is commonly used as insulation material.

There were options such as spraying urethane foam and "external insulation", which insulates the walls from the outside.

This time, due to budget constraints and consideration to the appearance of the building, we chose an internal insulation method, Styrofoam, although it was made of concrete (RC construction).

The thickness of the Styrofoam was 30mm for construction reasons.

*Styrofoam is a product that complies with the Green Purchasing Law.

Drilling core holes for toilet piping and ventilation fan (cutting holes for piping in the concrete wall)

The part covered by this wooden frame is the toilet.

In order to install a mini-kitchen in front of this, two pipes (one for water supply and one for drainage) extend towards the front.

At the top of the wall, a special machine was used to hollow out the concrete wall into a cylindrical shape to create a hole for the ventilation fan.

There was a Botton toilet a little far from this location, but it was removed during this construction project.

Construction of high insulation using sprayed urethane foam

Applying sprayed urethane foam in pinpoint areas such as around window sashes

Air-tight and insulated areas around toilet pipes with sprayed urethane foam.

I tried spraying urethane foam. It is so hard that if you put strong pressure on it with your finger, it will dent.

The urethane residue on my fingers could not be removed even after washing with soap for several days. It seems that it can be removed with thinner etc.

Making walls airtight with airtight waterproof tape (seal)

The black tape (seal) is waterproof and airtight, and is used to secure airtightness by securing the areas between the insulation materials and between the wooden frame and the insulation materials.

Highly airtight and highly insulated construction reduces heating and cooling costs and leads to a reduction in CO2 emissions. Furthermore, it helps create a comfortable working environment for seamstresses that is cool in the summer and warm in the winter.

Install bagged rock wool on newly created walls

Instead of a concrete wall, the new wall we built where there was no wall was made of wood, so we used Rockwool instead of Styrofoam.

The reason I didn't use glass wool was because I heard from a construction company that rock wool seems to have a slightly better humidity control effect.

I knew that the construction method of installing bagless glass wool or rock wool and then applying a moisture-permeable and waterproof variable sheet on top of that had great advantages, but I made the unfortunate mistake of forgetting to tell the construction company. The construction method has remained the same as before.

Also, I forgot to mention that if you install load-bearing walls (load-bearing facings) such as Hi-Vest or Dylite before installing insulation materials, it will have a positive effect on strength, airtightness, and insulation.

Rock wool is fluffy and looks like wool.

When you look at it from the front, it looks like sheep's wool.

Rock = Rock wool is called rock wool because it is shaped like this.

It is harder than wool.

I looked at rock wool from the side.

When you look at Rockwool from the side, you can see that it has a structure that resembles stacked crepes.

Insulating material is also installed in the gap between the pillar and the wooden frame for high insulation.

The blue thing in the gap between the pillar and the wooden frame is Styrofoam (the blue thing) that has been cut into small pieces.

Gap between ceiling and wall is insulated with sprayed urethane foam, secret construction

The gap between the wall and ceiling is insulated with sprayed urethane foam (the cream colored one) and kept confidential.